The Manufacturing and Engineering Process Team was founded in 2019 to organize the processes used by the club in designing and building high power rockets. I was a founding member of the team, and the second team lead, where I led the High Power Rocket Workbook project. The workbook is a set of process sheets that cover the most common design and manufacturing processes BYU Rocketry students use. The team conducted research on best practices in rocketry, decided on topics to cover, and learned about writing technical process documentation. As team lead, I directed the production of the workbook, writing many pages and taking on the role of editor.

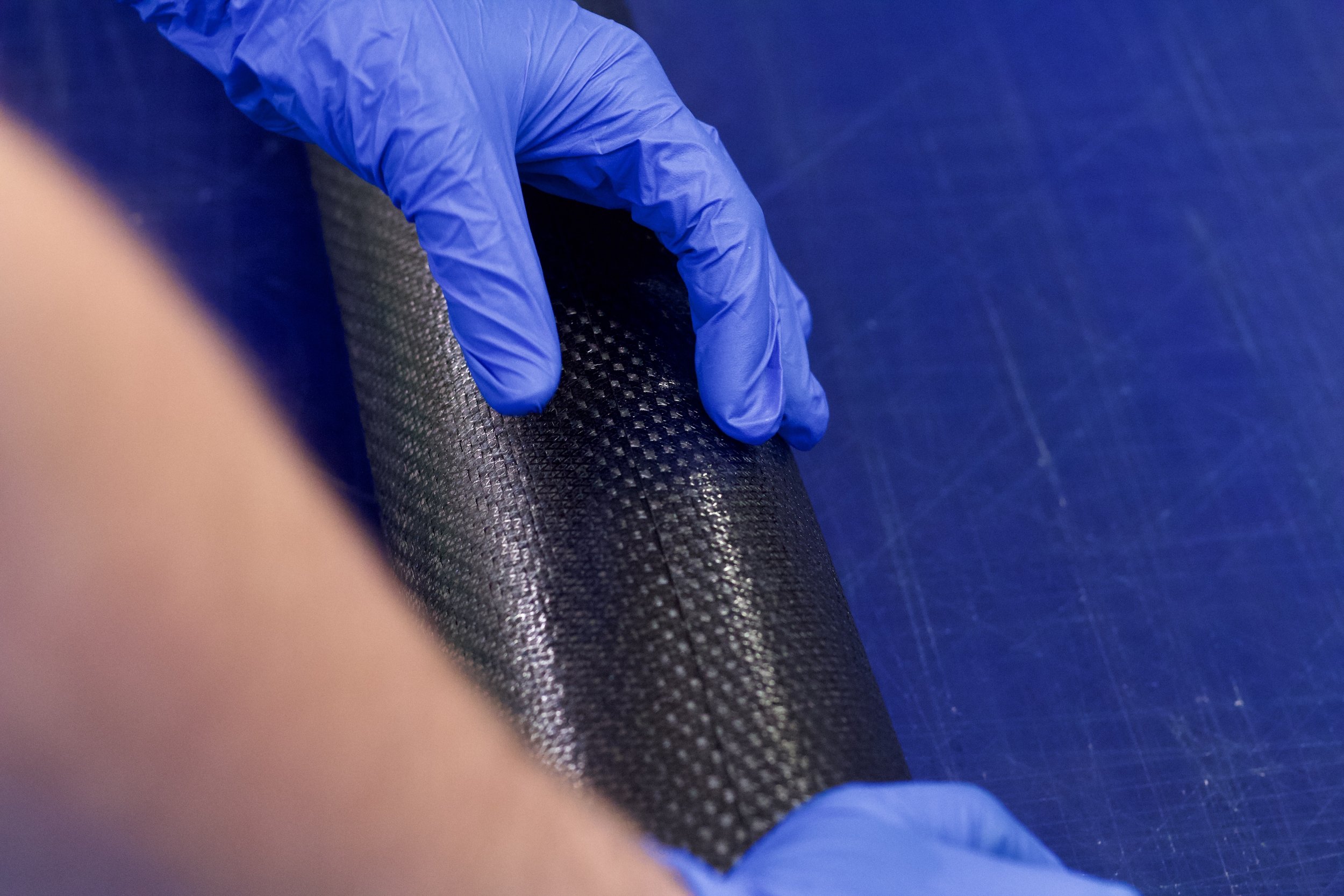

One process I had personally helped develop was making pre-preg carbon fiber body tubes. To preserve this method for future generations of BYU Rocketry students, I organized a demonstration and photographed key elements of the process.

The MEPS project served as a great exercise in leadership, research, and technical writing for me. It made me more aware of the problem in industry of retiring engineers leaving a vacuum of talent in the workforce, and I was able to attempt to correct this issue in the smaller-scale BYU Rocketry ecosystem. This project served as my Capstone project for my Applied Physics degree, focusing on applications in Aerospace Engineering, Manufacturing and Technical Writing.